Kocher+Beck manufacture a range of cylinders and rotary tools, which are key components throughout the printing and converting industries. Alongside the range of industry recognised tools Kocher+Beck also utilise their extensive experience in tooling technology and take your products to the next level, providing bespoke solutions to optimise your converting process. For detailed information, please click “More information”. Perfect cutting results everytime. Manufactured to the highest levels of quality and precision, and built to your specific converting/printing machine requirements. Magnetic force of 9.1 N/cm² as standard with ferrite magnets. Special higher forces of up to 5 x offered upon request with use of Neodymium, rare earth magnets. Highest possible dimensional accuracy. Each cylinder has axial positioning lines to ensure the flexible die is mounted correctly every time. Solid rotary tool offering long run capabilities. Precision engineered for excellent cutting results. Ideal for all common label applications. Manufactured using the latest CNC technology and with hardened bearers and journals and deep cutting blades for thicker substrates. Available in all common dimensions, with special sizes upon request. The hardness and surface finish can be tailored to suit your individual material or application. Highly annealed solid rotary tool for maximum performance. With all the benefits of our Standard Cylinder, but core hardened for maximum performance for challenging and abrasive materials such as metal foils or dense PVC. The hardness and surface finish can be tailored to suit your individual material or application. Manufactured from solid steel to prevent deflection and to ensure the highest quality of cut and finish. Specialist steels are available upon request. Perfect for ink and adhesive-free cutting edges. For all high ink and adhesive materials, choose either our Standard or Long-Life Cylinder and request our GlueX option. Proven protection against ink and adhesive build up on multi-layer and hot melt materials to protect the cutting edges. The hardness and surface finish can be tailored to suit your individual material or application. Precision perforations and cross cutting. Available for all standard machine types for perforating, kiss cutting and through cutting. Ideal for most self-adhesive and mono-materials, in-mould labels, thin film/liners, and paperboard. Clamping strips and counter clamps ensure cutting blades are fixed securely and replacement blades can be supplied for common designs. Maximum accuracy for outstanding print results. Made from rigid aluminium or steel, with low concentricity tolerances, due to our precision ground finishing process and can be supplied with a hardened anodized coating. Axial and radial positioning lines are available upon request to ensure that the printing plate is mounted correctly. The tool can be supplied with optional hardened and polished ground gears. Cylinders with larger dimensions are manufactured as “lightweight cylinders” by press-fitting flanges into an aluminium tube. With the identical quality of a solid print cylinder but weighing up to 75% less depending on cylinder dimensions. Precision results on even the most delicate of patterns. With the latest image and text processing systems alongside excellent technical capability, our hot stamping cylinders produce precise contours and accurate reproductions of even the most intricate designs. The smallest text and image motifs are milled onto the cylinders to a maximum depth. A unique polishing process is used to refine the cylinders even further and ensure unparalleled, brilliant hot stamping results. Maximum concentricity for running accuracy. Manufactured from core hardened tool steel and precision engineered for perfect cutting results and long service life. Designed with dimensional conformity to complement our range of magnetic cylinders and rotary tools with optional hardened and ground gears. Kocher+Beck anvil cylinders are precision ground for perfect concentricity using our modern CNC machining process. Perfect cutting results, every time. Manufactured from core hardened tool steel and precision engineered for perfect cutting results and long service life. Designed with dimensional conformity to complement our range of magnetic cylinders and hard tools. Kocher+Beck cylinders are precision ground for perfect concentricity using our modern CNC machining process. Perfect for complex contours and the finest punching. Precisely manufactured ejector pins, individually tailored to your requirements and specially developed for the highest demands in cutting technology. An extensive selection of materials enables optimal adaptation to every production requirement. Highest precision and repeat accuracy. Each ejector cylinder ensures clean and controlled ejection of the cut material – even with complex contours and the finest details. For side, separation to window cuts or perforations. Whether you need side, separation, or window cuts, we have the perfect carrier system for your application. Our product range includes both single and multiple suction options with our standard cylinders. Speciality or custom products are available upon request. Precision made with advanced CNC technology. Our GRANOtec magnetic flat bases are manufactured from the highest quality scratch resistant non-metallic material to prevent mechanical stress or distortion. Manufactured to the highest dimensional accuracy to ensure even cutting over the entire surface. We offer standard format flat bases with special sizes upon request. Rotary Tooling + Magnetic Cylinders

Precision engineered cylinders and rotary tools, manufactured to the highest industry standards, and designed for numerous materials from self-adhesive labels through to medical and industrial applications.

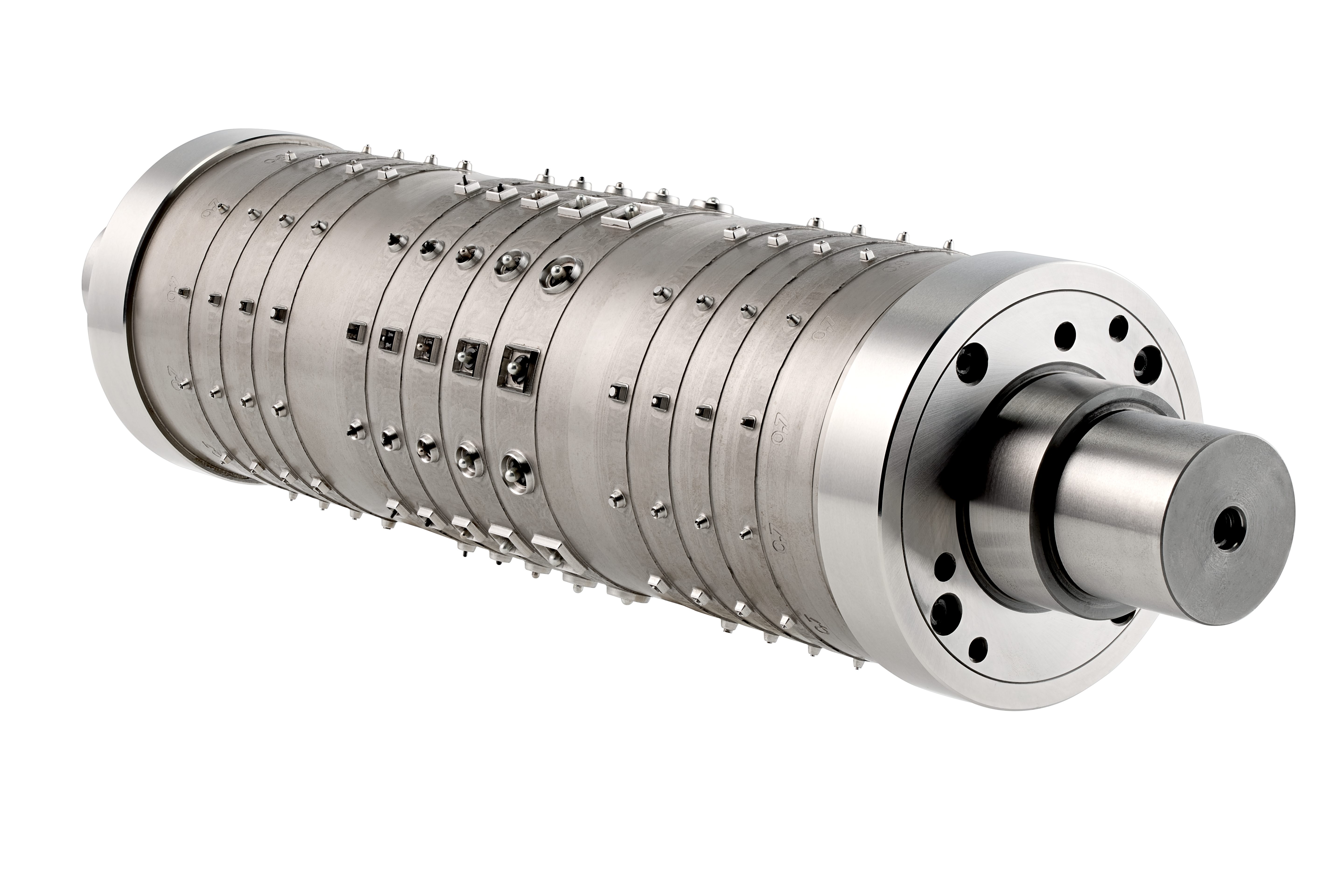

Magnetic Cylinder

Overview:

Benefits:

CUTTING CYLINDER

Overview:

Benefits:

LONG LIFE CYLINDER

Overview:

Benefits:

GLUEX CYLINDER

Overview:

Benefits:

CROSS CUTTING CYLINDER

Overview:

Benefits:

PRINTING CYLINDER

Overview:

Benefits:

HOT STAMPING CYLINDER

Overview:

Benefits:

ANVIL CYLINDER

Overview:

Benefits:

Longitudinal / Slitting Cylinder / Remaliner

Overview:

Benefits:

Ejector cylinders

Overview:

Benefits:

MAGNETIC ENVELOPE CYLINDER

Overview:

Benefits:

MAGNETIC FLATBASE

Overview:

Benefits: